Thermal insulation is one of the first aspects that should not be underestimated in the construction or renovation of any type of building, especially if it is the one where we live or where we have to live.

He is about to end up run over, his mother saves himTwo systems, one hot and one cold, always tend to reach a balance, transmitting heat to each other. We cannot stop this motion by going against the laws of physics, but we can slow it down in our homes to meet the wallet and the environment.

Limiting the dispersion of heat from the inside to the outside of buildings is, in fact, one of the main ways to save energy which becomes a priority especially in the presence of structures built a few decades ago, when the formation of thermal bridges, much less of the problems related to the reduction of consumption energetic and environmental impact. With the consequence of strong heat losses and the mold formation especially on the north walls of the buildings which affect not only the domestic economy but also, and above all, the quality of life.

A man spends most of his life indoors, in places like his home or workplace. This is why he must enjoy the maximum living comfort in order to obtain psycho-physical well-being. A first fundamental step, therefore to gain health and save money, is to create a correct and adequate thermal insulation of your home through materials and processes as bio-compatible as possible.

The techniques available today make it possible to solve the problem on several fronts. To reduce heat loss and eliminate drafts, in addition to intervene on the glass, by installing double ones, it becomes essential to isolate the vertical surfaces of the building most exposed.

The best thermal insulation, which has taken hold in Europe in the last 30 years, is undoubtedly the so-called one coat, made with materials that make the cladding and internal partitions insulated, but at the same time breathable. This happens because a sort of living envelope is created, which allows man to be able to choose to remain inside an environment both in winter and in summer, because it protects him and allows his body to breathe.

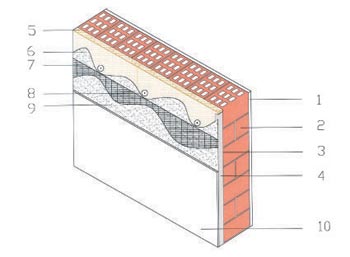

L'' external thermal insulation, in practice, it consists in applying insulating panels to the entire vertical external surface of the building which are then covered by a thin finishing thickness made with special plasters.

Index

What are the advantages of external thermal insulation?

1) A continuous and uniform insulation that allows the total elimination of "thermal bridges" by increasing the building's capacity to retain heat;

2) the elimination of mold on the internal surfaces of buildings;

3) the protection of the external walls from atmospheric agents;

4) stabilization of the thermo-hygrometric conditions of the building structure;

5) the reduction of the thickness of the perimeter walls with the consequent increase of the living areas;

6) the improvement of the thermal flywheel of the perimeter walls;

7) slowing down the process of deterioration of buildings;

8) the elimination of the problem of water infiltrations and cracks.

Furthermore in the case of restoration and renovation of existing buildings, the external insulation system, not requiring the removal of tenants during the execution of the works, but above all allowing the realization in a single phase of the insulation and finishing, entails a series of significant advantages both from the organizational side and from the economic saving.

Which one to choose?

To obtain an effective external insulation system, the utmost attention must be paid to the characteristics of the individual components, in particular of the insulating material chosen based on its performance and its pockets. Four different materials can be used for the panels:

Cork

It constitutes the superficial layer that covers the bark of large trees, but above all of the cork oak, a very "long-lived" Mediterranean plant (100-150 years). A very important aspect is that it is a local plant. We find it in Sardinia, Sicily and Tuscany, which allows us to reduce the transport of the material itself with a significant reduction in pollution. In addition to meeting the requirements for optimal thermal insulation, cork also acts as an acoustic absorber, thanks to its particular structure. Furthermore, its high vapor permeability guarantees a very comfortable indoor climate.

The mineral rock wool

It is obtained from the melting and spinning of natural rocks at a temperature of 1500 ° C. The open cell structure makes it the only material capable of satisfying four needs: incombustibility, sound absorption, thermal insulation and fire protection. Precisely for this reason it is widely used in those buildings for which the laws require fireproof construction materials. Furthermore, rock wool is a chemically neutral material, which prevents fungi, molds, microorganisms and bacteria from developing. Perhaps the only two "contraindications" lie in the fact that its installation must be carried out with great caution and with the right protections, since it is a material recognized as non-carcinogenic (IARC, 2001) but can be irritating to contact. Furthermore, it must always be coupled to a vapor barrier to prevent condensation from diminishing its thermal insulation characteristics.

The wood fiber

This insulation system meets all the requirements of an environmentally friendly material, from production to eventual disposal. In fact, the raw material is wood, a natural and renewable material; its production process does not damage the environment and its mechanical characteristics are excellent from a technological point of view: it is permeable to vapor, it regulates the humidity of the environment and is absolutely safe during installation.

Calcium silicate

Naturally, this system also combines insulation requirements with biocompatibility characteristics. Quartz sand is combined with lime first and then with cellulose, creating a sort of natural reinforcement. They are self-supporting and light at the same time, they can be cut and laid very easily, applying special adhesives that allow capillary adhesion between the wall and the panel itself. Totally fireproof, the panels have a PH equal to 10, thus also acting as a barrier against molds.