What if you could build your own wooden house yourself using 3D printing and using the Lego scheme? It is not fantasy but an already established idea that bears the signature of the British architecture firm Facit Homes. At the base there is the D-Process, a prefabricated building technique that exploits the possibilities of new technologies for printing

He is about to end up run over, his mother saves him

What if it were possible to build your own wooden house using 3D printing and exploiting the scheme of Lego? It is not fantasy but an already established idea that bears the signature of the British architectural firm Makes Homes. At the base there is the D-Process, a machine based on a prefabricated construction technique that exploits the possibilities of new printing technologies.

The population is growing and the construction of new homes cannot keep up. But the D-Process could be a solution, thanks to the ability to design your own home, print the “pieces” on the spot and then quickly hooked up like large blocks of Lego.

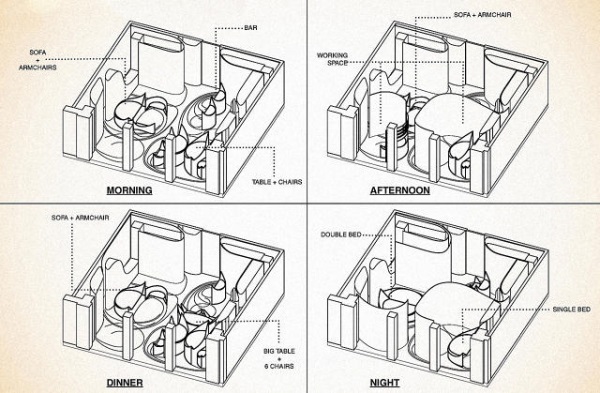

The construction. The houses are first designed on computers, with every little detail broken down into the smallest detail, thus allowing the client and future landlord to organize the space according to personal needs. A container inside which the 3D printers are located, it is positioned in front of what will become the front door and cuts the wooden walls to obtain the precise size.

Thus was born the "frame" of the future house, a "big wooden Lego", like thehe defined Bruce Bell, head of Facit Homes. These pieces are already complete with all the holes needed for mounting, insulation, plumbing and electrical systems.

Each home includes thermal insulation, energy savings and minimizes heat loss. Depending on the site requirements, there are a number of additional systems such as solar and photovoltaic systems that can be incorporated into the building to make it even more efficient.

I advantages environmental, according to the creators, they are not indifferent. In fact, all the expensive logistics of large factories are avoided, eliminating the emissions caused by the transport of materials and reducing waste to a minimum. In fact, only what is needed is produced, without waste.

The advantages of the “D-Process” technique cover practically every aspect of the construction. It is much faster to assemble: a four bedroom home can be built in less than a week. It needs fewer materials, which means it is substantially greener. It requires a small workforce, so it is cheaper.

The D-Process is gaining momentum in the UK. Among some examples already made there are Villa Asserbo in Denmark and the Hertfordshire House in Great Britain, built on site. The latter has an area of 200 square meters while the layout of Villa Asserbo, made from 800 sheets of sustainable plywood, makes the most of natural light for lighting.

Francesca Mancuso

Designtoimprovelife

READ also:

The green house? Ready in 24 hours with 3D printing

Ad Amsterdam la prima casa stampata in 3D (PHOTO and VIDEO)

Legologica: the 0 km ecological house that can be assembled like legos

Treehouses: the Ewok-style LEGO village (video)