3D printed photovoltaic panels developed by a Newcastle University research group will power the 15.100km car journey that begins in September. The initiative is part of the Charge Around Australia project

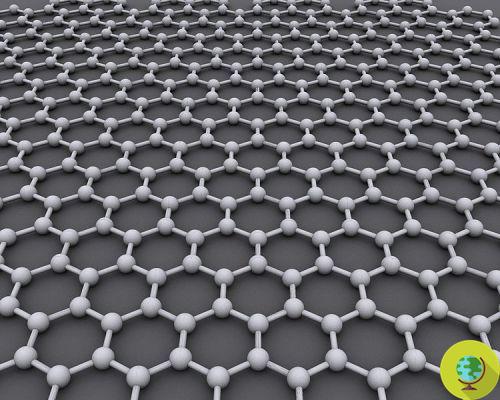

He is about to end up run over, his mother saves him18 3D printed flexible solar panels to power a journey of 15.100 km of a Tesla car: this is the challenge of the Charge Around Australia project. Each panel is 18 meters long, which can be "rolled up" on the vehicle to recharge it, transforming, like any self-respecting photovoltaic system, the energy of the Sun into electricity.

In 2020 the technology was brought to the first public demonstration, in which the panels were installed within the new and vibrant urban space of the Lane Cove Council ‘The Canopy’.

Read also: 3D printed flexible photovoltaic panels are now the reality, lightweight, recyclable and economical

Reached the marketable pilot scale, now the most important test, which will evaluate several factors including the resistance of the panels themselves but also their potential performance for other applications.

This is actually a ideal test bed to provide us with information on how to use and power the technology in other remote locations, such as in space

Paul Dastoor, chief inventor of the technology, told Reuters

This project seeks to demonstrate how printed solar technology can be used in remote and real environments for charging of electric cars off the grid - Rather than developing special solar vehicles or using commercially available heavy solar panels, the project will use lightweight printed solar panels. We will transport them to the back of a commercially available electric vehicle and then unroll them to charge the car as needed

The proposed route runs the entire coast of Australia and therefore will test vehicles and solar technology in some of the country's most remote and challenging regions.

©Charge Around Australia

All in a rather economical way. In fact, the material, similar in thickness and appearance to a chip package, is produced using conventional one printers cost less than $ 10 per square meter and the completely conventional printer was originally used for the production of wine labels.

The material, similar in thickness and appearance to a package of chips, is produced using conventional printers at a cost of less than $ 10 per square meter. The printer was originally used for the production of wine labels.

(The) community is looking for these kinds of answers to the problems presented to them, day in and day out, about climate change

Dastoor also says that with this trip he wants to provide citizens with a demonstration on how climate change can be fought

The Tesla journey will in fact last 84 days, during which the team plans to visit around 70 schools to give students a taste of what the future might hold. And the researchers hope that Elon Musk, founder of Tesla Inc., will be satisfied and maybe, who knows, decides to invest again in the green turning point.

All ready for the journey of the future?

Follow your Telegram | Instagram | Facebook | TikTok | Youtube

Sources: Reuters / Charge Around Australia

Read also:

- The adhesive photovoltaic panels that can be installed anywhere like the stickers of an album

- Solar panels on the roads, the new frontier for fueling the energy transition in Europe