The future of renewable energy lies in 3D printed flexible photovoltaic panels. The technology, the work of a research group at the University of Newcastle (Australia) is now on a commercial scale pilot scale

He is about to end up run over, his mother saves him

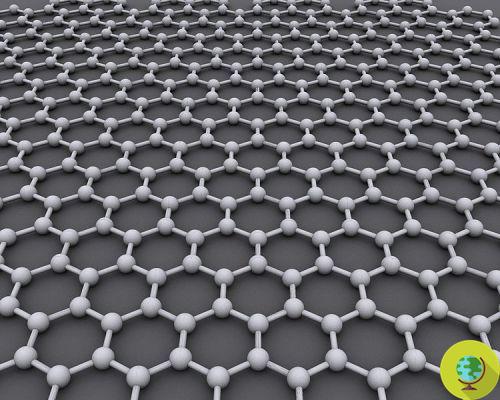

3D printed flexible photovoltaic panels: here is the future of renewable energy. The technology, now in a pilot scale at a commercial level, is the result of a research conducted by the University of Newcastle (Australia) which showed that the panels produced in this way are also ultralight, recyclable and economical to produce.

The material, similar in thickness and appearance to a chip package, is produced using conventional printers. In 2020 the first public demonstration, in which the panels were installed within the new and vibrant urban space of Lane Cove Council ‘The Canopy’.

Globally, there are very few installations of this type and therefore we don't know much about their performance in a public environment - explained Paul Dastoor, who led the studio - This is the next fundamental step to accelerate the development and commercialization of this. technology. It presents us with a new scenario to test performance and durability that can cope with one series of new challenges

Technology

According to the researchers, this technology will change and really revitalize some solar printed as products can be produced on conventional printers. Plus the material is extremely light, hyperflexible and incredibly thin.

Printed solar also appears cheap, with a production cost of less than $ 10 per square meter and quick to produce, with commercial-scale equipment capable of producing miles of material per day.

No other renewable energy technology can be produced so quickly Dastoor already explained at the time - The low cost and speed with which this technology can be implemented is exciting as we have to find solutions and quickly

The last but not the least, the products underlying the technology can be recycled, a distinct advantage over traditional silicon panels, as over 99% of the panels are made up of PET.

Where are we

We are currently studying the recycling processes for this material - the scientist reported on this in 2020 - Our hope is to be able to separate the outer layers of PET and reuse them to create new panels with minimal processing "

And the research, meanwhile, has continued, leading to the technology up commercial pilot scale.

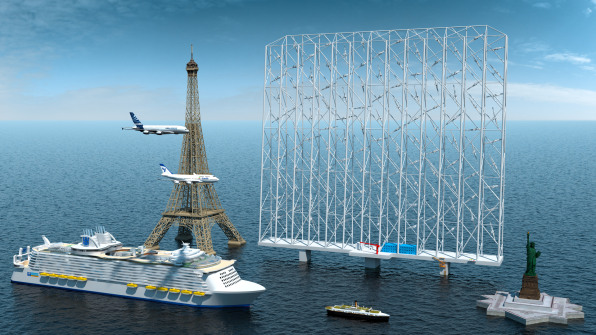

The low cost, light weight, flexibility and durability of the material also continue to inspire one range of possible applications, including disaster relief and recovery, retractable charging systems for electric vehicles, caravans / camping and defense industries, floating covers for dams and swimming pools, sails for yachts, smart tents for residential and high-rise buildings, greenhouse covers and more.

Imagine a world where everyone has access to electricity and where every surface can generate clean energy, low cost and sustainable from the sun. It's a world I want to live in "

concluded Dastoor.

How to blame him ...

Follow us on Telegram | Instagram | Facebook | TikTok | Youtube

Sources: Newcastle University / Newcastle University / Youtube / Newcastle University / Product fact sheet

Read also:

- Photovoltaics from the balcony as an alternative to gas and against expensive bills

- Photovoltaic on agricultural roofs, incentives are on the way that can save companies from expensive bills