New research has found a way to recycle plastic so it can be reused over and over again.

He is about to end up run over, his mother saves himThe chemistry of plastic makes it more difficult to recycle; even thermoplastic materials, which can be melted, weaken with each reuse, and this represents the real barrier to recycling: the economy, there is simply no incentive to profit. But now a new one study turned the tide, discovering a method of breaking down plastic to create a new material that is stronger and more durable than the original, meaning it is potentially more valuable.

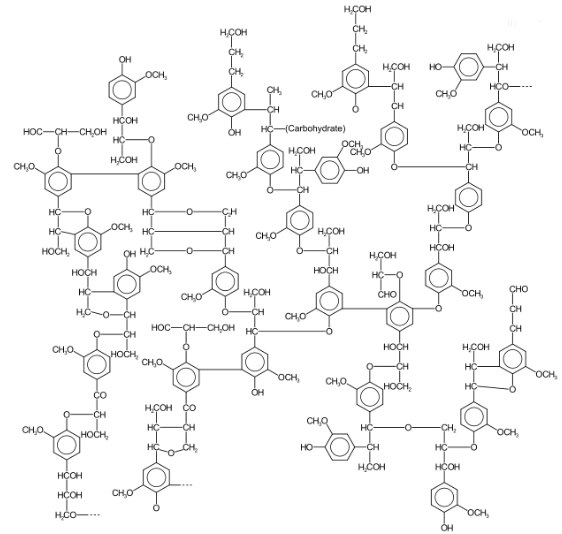

The goal is that through this method a economic incentive to recycle plastic, literally turning trash into treasure. Carbon-hydrogen bonds are some of the strongest chemical bonds in nature, their stability making it difficult to transform natural products into medicines and difficult to recycle base plastics. But by modifying the carbon-hydrogen bonds that are common in polymers, the building blocks of plastics used in grocery bags, soft drink and water bottles, food packaging, auto parts and toys, the shelf life of polymers could be extended beyond single use.

With a newly identified reagent capable of removing hydrogen atoms from medicinal compounds and polymers, chemists were able to create new bonds in places previously considered non-reactive. The versatility of the approach is that it allows for many valuable transformations, across a wide range of important compounds.

A systematic review

The team of researchers has developed a superabsorbent polymer, capable of removing hazardous chemicals from drinking water. The researchers envisioned using the innovative approach, however transform difficult-to-recycle plastic waste into a high-value class of polymers.

They started with plastic foam packaging used to protect electronics during shipping. The foam is made from a low-density plastic, called a commercial polyolefin. By selectively extracting hydrogen atoms from polyolefin, chemists have come up with a way to expand the life of single-use plastic into a high-value plastic, known as an ionomer. One popular ionomer is Dow's SURLYN, a reference material used in a wide variety of food packaging.

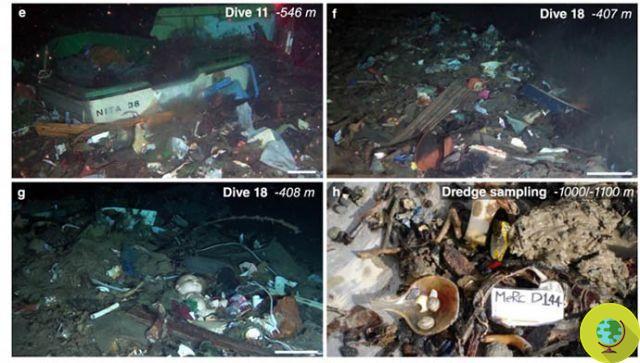

Most of the recycled plastic is transformed into lower quality products, such as carpets or polyester clothing, which could still end up in landfills; without forgetting that the plastic discarded in waterways endangers marine life. But if chemistry can be repeatedly applied to polymers in order to recycle them over and over again, it could change the way we look at this material today.

Follow us on Telegram | Instagram | Facebook | TikTok | Youtube

Photos: Science Daily

Could it be interesting for you:

- Can plastic-eating "superenzymes" really curb our waste problem?

- Sweden trains crows to collect butts, but it's the people we should be educating

- Goodbye plastic, Lidl develops edible film based on food waste for fruit and vegetables

- Greenwashing of coffee capsules: millionaire fine for Canadian producer who lied about recycling

- Disposable paper bags are no more environmentally friendly than plastic ones, according to the German study

- Organic waste: from January 2022 the obligation to collect wet waste and bioplastics in all municipalities has begun

- Transforming plastic waste into innovative and low-cost prostheses, the start-up that gives hope to those who could not afford them

- The ban on plastic packaging for fruit and vegetables in France is underway