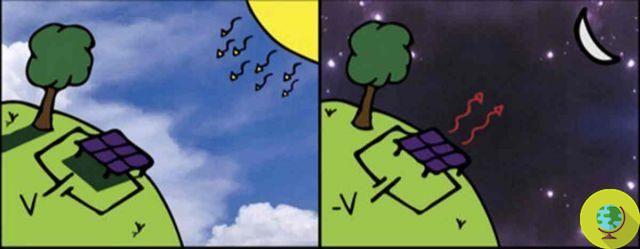

Photovoltaics has never had such a bright prospect. Scientists from Sandia National Laboratories have developed a system of photovoltaic cells as small as glitter that could revolutionize the way solar energy is stored and used.

He is about to end up run over, his mother saves himIl PV never had perspectives so "sparkling". Scientists of the Sandia National Laboratories have developed a system of Photovoltaic cells as small as glitter that could revolutionize the waysolar power it is accumulated and used.

As reported by ScienceDailyIndeed, the glitter cells theoretically they could turn a person into a solar battery charger walking if they were fixed on flexible layers such as clothing.

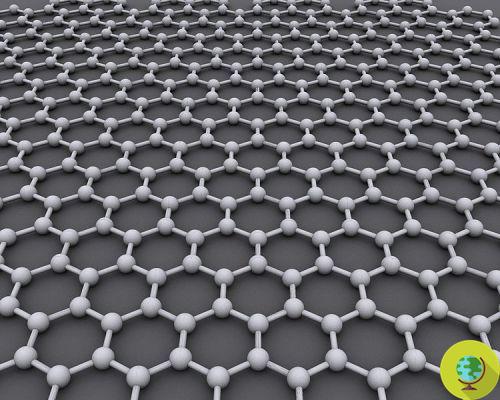

Thinner than a human hair (which is about 70 micrometers thick) and with a diameter ranging from 14 to 20 micrometers, these solar micro-cells are 10 times smaller than conventional ones, able to guarantee, however, the same efficiency it's a greater versatility in use. In addition to reducing production costs.

Manufactured in crystalline silicon and assembled using systems microelectronic and electromechanical MEMS - common techniques in today's electronics - in fact, the solar microcells developed by the photovoltaic department of the research laboratories of the American Department of Energy, lend themselves to an infinite number of new practical applications and have dozens of advantages. Research coordinator Sandia Greg Nielson identifies at least 20 and explains how, for example, "the units could be mass-produced and wrapped around unusual shapes for the construction of solar curtains integrated or clothing. In this way it would become possible for hunters, hikers or military personnel to recharge the batteries for phones, cameras and other electronic devices simply by walking or resting in the open air “.

Furthermore, one of the greatest advantages of these microcells would be the significant reduction in production and installation costs compared to the current ones solar panels and photovoltaic techniques: being so small, in fact, they require fewer materials to form highly efficient devices. To be precise, according to Nielson, the same amount of electric energy it would be produced using one hundredth of the silicon of traditional solar cells.

The less material used to build them, the less mechanical deformations, greater reliability and flexibility in production processes. But not only that, because having such a thin diameter, the "glitter" cells can be manufactured on an industrial scale and produced with wafers of any size: each cell, a bit like the techniques used for LEDs, would be applied on a silicon wafer and then composed in hexagonal shapes with the electrical circuits printed on each piece. In this way, if a cell turns out to be defective, it could be safely isolated from the rest, contrary to what happens in current productions where there is the risk of compromising and making the whole wafer unusable.

Among the other Nielson listed advantages, the better shade tolerance, the greater ease of production and consequently the reduction of costs by implementing economies of scale: the pick-and-place machine, for example, a tool that assembles electronics products widely used in the commercial field, would be able to insert up to 130 thousand units of micro-cells per hour at a cost of about a tenth of a cent for each module capable of containing from 10 thousand to 50 thousand cells.

After the space and the hair, therefore, the photovoltaic of the future it has a new and "shiny" path to aim for.

Simona Falasca