German start-up Polycare has created 100% eco-friendly bricks using desert sand and construction scraps.

Does it seem like a child's activity to assemble and disassemble a construction just like you do with Legos? Wrong! From today it is possible to create comfortable homes using recycled, recyclable and movable bricks, that is, they can be disassembled and reassembled elsewhere.

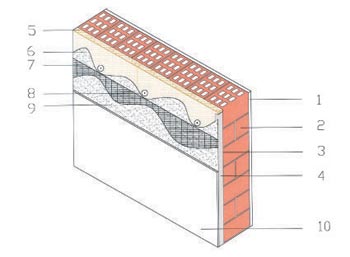

The Polyblocks, the latest invention of the German start-up Polycare, look like the largest version of the famous bricks, but, unlike them, they can be used to build real houses. They also provide an environmentally friendly alternative to traditional building materials.

The idea came after the catastrophe in Haiti

Polycare Chief Operating Officer Andreas Kunsmann said in reference to the 2010 earthquake, adding that the company's founders have thought about

how to radically change the construction process and allow people to build houses on their own with local products

With a modular construction system similar to Legos, the Polyblocks allow even the most disadvantaged sections of the population to build their homes with affordable prices and natural materials.

In fact, the blocks can be made with desert sand or with recycled building materials without the use of water. In addition, the binder is partly made up of recycled PET bottles. The company hopes to bring greater accessibility and sustainability to the construction industry, so much so that the company has already built around 100 homes in Namibia for people in financial need.

View this post on Instagram

A post shared by Polycare (@polycare)

Currently the most common construction material is cementitious concrete, the manufacture of which is responsible for 6-9% of all annual anthropogenic carbon emissions (̴3 billion tons of CO2). Polycare bricks, made of polymer concrete - composed of 90% natural sands and 10% of binder - are therefore an excellent alternative. The other advantages of the material are resistance to water and UV rays, insensitivity to temperature changes and recyclability.

View this post on Instagram

A post shared by Polycare (@polycare)

Kunsmann added:

We need very few materials to make a brick. The smallest block we produce to build requires 75% less material than a classic brick. In addition, our material is up to five times stronger than normal concrete.

Polycare's vision is to revolutionize the traditionally linear construction sector by making it circular and promoting a modular construction system. Alternatives of this type, in addition to reducing carbon emissions, allow a more equitable and far-sighted development model, guaranteeing a more widespread and more sustainable condition of well-being even in the long term.

Read also:

- The start-up of this Kenyan woman recycles tons of plastic into bricks harder than concrete

- This Indian startup turns polluted air into beautiful tiles

- Schoolgirl transforms old clothes into heat-insulating bricks